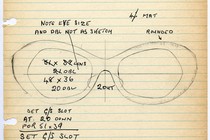

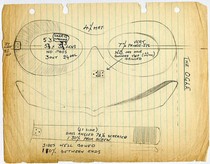

From its founding in 1926 through the early 1970s, all Oliver Goldsmith frames were made by hand in the company’s Poland Street workshop. The company started with the design, in the form of a hand-drawn sketch.

The frame makers would then cut a slab of plastic into the desired shape for the frame and its sides; file down the edges; attach the sides; sand down the finished design; and fit the lenses. Depending on the complexity of the design, the process of making a frame by hand would take from six hours up to several days.

Many of the workshop staff stayed with the company for decades. Retired glazer Harry Swain worked for Oliver Goldsmith from 1946 until 1983. He recalls, ‘I left school at the age of 14 years in 1932 so I had to decide which trade to go into. I decided to go into the optical industry. When I was demobbed in 1946 I went to work for Oliver Goldsmith, where I remained until I retired in 1983.

1. Inside the Oliver Goldsmith workshop in 1966

Pattern maker Ron Saich selecting the material

2. Inside the Oliver Goldsmith workshop in 1966

Using a sharp/pointed metal scribe, pattern maker Ron Saich scribes the frame shape onto the plastic

3. Inside the Oliver Goldsmith workshop in 1966

Using a fret saw, Ron Saich drills two holes and then cuts out the eye shapes; he will then cut around the outside of the frame shape

4. Inside the Oliver Goldsmith workshop in 1966

Ron checks the measurements

5. Inside the Oliver Goldsmith workshop in 1966

Another frame maker shapes the front of the frame with a scraping knife

6. Inside the Oliver Goldsmith workshop in 1966

Warming the front on a hot air heater allows the frame maker to 'bump the bridge' into shape; which means creating the space to accommodate the nose, thus making it more comfortable to wear

7. Inside the Oliver Goldsmith workshop in 1966

Filing the front into shape

8. Inside the Oliver Goldsmith workshop in 1966

Sanding the frame to get rid of the filing marks

9. Inside the Oliver Goldsmith workshop in 1966

Checking that the eye size is correct

10. Inside the Oliver Goldsmith workshop in 1966

Fitting the front half joints by heating the tool and using it to push the metal hinge into the front

11. Inside the Oliver Goldsmith workshop in 1966

Frame maker and workshop manager, Tom Eley, fits the half joints into the sides. The photograph shows a work bench full of orders waiting to be processed. Each order had its own cardboard tay with a works docket containing the order details.

12. Inside the Oliver Goldsmith workshop in 1966

Frame maker at the hard polishing mop machine removing filing scratch marks

13. Inside the Oliver Goldsmith workshop in 1966

Polishing at the soft polishing mop machine to remove all final scratches

14. Inside the Oliver Goldsmith workshop in 1966

Checking that the sides are parallel. In this process the frame maker would heat the frame over the Bunsen burner to warm the frame and make it more pliable to allow for small adjustments. After making these adjustments, the frame maker would pluge the frame into cold water after adjusting it to the correct fit. The photograph shows a bucket of cold water on the left. On the workbench you can see many tools such as pliers, files and joint screws (in the small box).

15. Inside the Oliver Goldsmith workshop in 1966

A view of the top floor workshop at 60 Poland Street, showing the frame makers at work. To the left is racking stacked with the plastics used for frames. Fans helped cool the workshop when the Bunsen burners and hot air heaters were in used. At this time, Oliver Goldsmith employed around ten frame makers in the workshop. Oliver Goldsmith's frame makers were usually employed for decades; many of them worked for the company for between 20 and 30 years.

16. Inside the Oliver Goldsmith workshop in 1966

Oliver Goldsmith's workshop with orders waiting to be processed

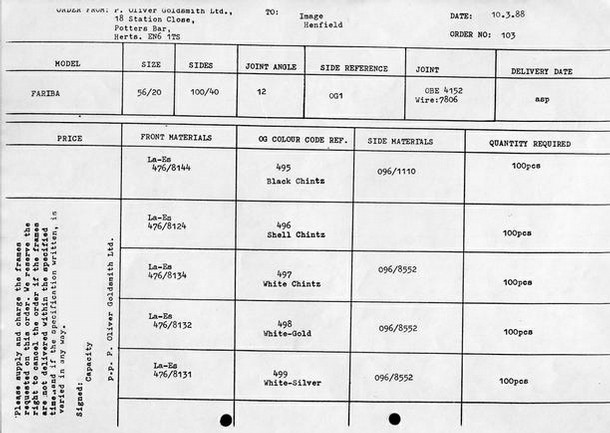

In 1972 Oliver Goldsmith moved its offices from Poland Street to Potters Bar, Hertfordshire. At this time, the company was transitioning from making all its frames by hand to making semi-handmade frames. This process still started with the frame styles designed in-house. Pre-ordered plastic was then delivered to factories in London, Essex and Brighton to be cut into the desired shapes by machine. The frames were then assembled and finished by hand. By the early 1980s, though their prototypes were still designed in-house, all Oliver Goldsmith glasses were completely mass-produced in a Brighton factory. A surviving order form shows how manufacturing information was communicated to the factory.

From the 1960s through the 1980s, the company produced new styles on a regular basis. Once these new frames were produced, the company salesmen would take a set of samples of these new styles to show to opticians across Britain. For the foreign market, A Oliver Goldsmith travelled regularly to the United States, Canada and Europe to present the collection and take orders. The company would ship frames to the distributor who would then sell them on to the foreign opticians. The United States, Europe, Scandinavia and South Africa were the company’s main overseas markets.

Since 1989 A Oliver Goldsmith has run the eyeglasses company as a licensing business and creates the looks which the licensees select from. Oliver Goldsmith frames are sold in Korea, Japan, Europe, Australia, the United States and Canada. In recent years Oliver Goldsmith has revived a number of its most popular original designs.International Training Course

The Victoria and Albert Museum welcomes applications for ‘Creating Innovative Learning Programmes’, its new one week intensive course. This is a unique training opportunity for museum professionals from overseas who are interested in attracting and programming for a range of museum audiences.

Find out more