Conservation Journal

April 1994 Issue 11

Treatment of an early 18th Century Indian chintz qanat

Introduction

Over the last 30 years, the use of thermoplastic adhesives has become an established choice of treatment in the support of fragile textiles. During that time, the Textile Conservation Section at the Victoria and Albert Museum has evolved an expertise in the application of the poly (vinyl acetate) emulsion Mowilith DMC2 when such a treatment is appropriate. The methods of application are continually being refined. The recent conservation of an early 18th century chintz qanat for the Nehru Gallery of Indian Art afforded an opportunity to clarify thinking about the use of adhesive techniques and to further refine methods, in particular, the use of low pressures on the vacuum hot table.

The Qanat

The qanat (Museum no. IM29 1928) is one panel, measuring 71 by 217 cm, cut from a larger length of repeated niches which would have formed a tent wall (Fig.1). Off-set from the centre there is a vertical seam made with long loose running stitches along the selvedge allowances of two part loom-widths of plain weave cotton. The chintz design is made in the traditional kalamkari technique of printing, mordant dyeing and overpainting to produce a predominance of red and green with purple, brown and yellow, the natural ground of the cotton left to depict the main motifs of the irises and surrounding flowers.

Condition

The overall condition of the cotton is generally sound in both the fibre and weave structure but various types of degradation and damage occur throughout. There is a distortion of the cloth at either end of the seam: this is probably due to each piece having been pinned out at the corners while the design was first drawn, printed and painted. Also from the original making, the iron mordant used to create the brown and purple colours from madder in the dyeing process has caused a characteristic degradation of the cellulose fibre in these areas. Further thinning and breaking of the fibre has occurred at some time past in areas of mould growth. The rough cutting of the panel has left jagged edges and a careless slit parallel to one side and there is more mechanical damage in splits and tears. One mould damaged flower has been 'tidied' by cutting away and patching with a similar motif stuck behind with a green starch paste.

Treatment

The chintz is unusual in its preservation of original overpainting in the yellow motifs and the green areas where saffron or turmeric has been applied alone or over indigo. Very often in such textiles this has been diminished or removed completely by previous washings. For this reason wet-cleaning could not be considered in the present conservation treatment. However, vacuum cleaning with small aperture low suction equipment was found to efficiently remove particulate dirt and loose degraded fibre.

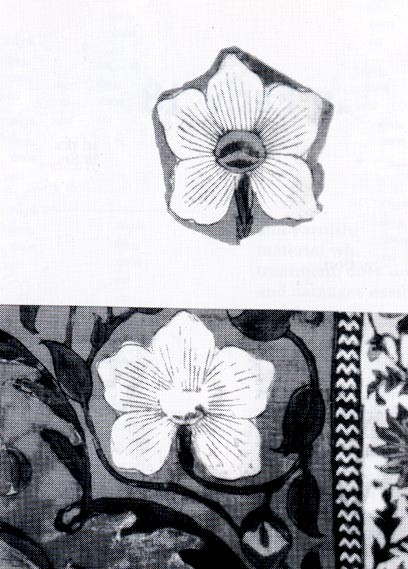

Fig. 2 The old patching repair of a similar flower motif and the residue of dry paste were removed (click image for larger version)

The old patch repair was easily peeled away and the residue of dry paste was removed as far as possible with a spatula (Fig.2). Relaxation of creases and folds was made by humidification using an overall dampened poultice, moisture being kept to a minimum so that the overpainting was in no way disturbed.

To use a stitching technique alone to support the qanat would only cause more disintegration of the degraded brown and purple motifs and leave them vulnerable to further deterioration: the passage of a needle through these would invariably break up the weave structure and couching threads would not be sufficient to prevent continuing breakdown of the brittle fibre. However, an adhesive technique could first be used to consolidate both the fibre and the weave and then stitching could complement this treatment by helping to hold the most vulnerable areas in contact with the support when the textile was hanging for display.

Mowilith DMC2 poly(vinyl) acetate thermoplastic adhesive was mixed as a 15% solution in deionised water and cast with a brush onto a Stabiltex 4 polyester substrate using approximately 100 ml per square metre. Polythene sheeting was used as a release surface to minimise the shine on the resulting film.

Initial adhesion of this support to the textile was made by hand, using domestic irons at a temperature of 90°C with the object laid face down over layers of flannelette sheeting covered with Melinex. The Stabiltex film was bonded to it aligning the weave squarely from the centre outwards, working each cotton width separately and taking the support into the seam and over the selvedge allowance. At this stage fragments, splits and distortions were avoided; the sound areas were set carefully

and correctly around them. A compromise of alignment was necessarily made at the fluted ends of the seam. The seam stitching was reinforced following the original stitchholes taking new thread through both support and object. Then with the textile face up and using spatula irons at a temperature 80-90°C, the fragile, split and distorted areas were adhered. Silicone release paper was used throughout between textile and iron.

A consolidation of this initial adhesion was now made using the vacuum hot table. The object was laid face up over a Melinex isolator on the table surface and held at its natural tension using tape along the edges of the Stabiltex support. The fluted ends of the seam were padded out with tapering layers of polyester wadding isolated with Melinex. Strips of polyester wadding were laid along either side of the object linking it to the channel around the edge of the table from which the air would be pulled by the vacuum pump. The areas of exposed adhesive film were covered with silicone release paper to prevent shine before the vacuum 'envelope' was completed with a total covering of Melinex. The table was heated to 60°C and then a pressure of 40 millibars gauge was drawn, to hold the object and support in close contact while the heat activated the adhesive and ensured a consistent overall bonding.

The consolidated textile could now be given a secondary backing of cotton lawn, supporting first throughout with an alternating grid of staggered running stitches (Skala polyester thread) and then more specifically in the most degraded and damaged and still vulnerable areas with laid couching stitches (pulled Stabiltex thread). For display the top edge of the qanat was held over the curve of a roller (attached by an apron) and allowed to hang freely down.

Conclusion

The means of display for the object was chosen (within the parameters of safety) to preserve its essential qualities as a textile. The methods of conservation were chosen likewise. Humidification removed general creasing and the buckling caused by old pasting but did not flatten or completely straighten as wet-cleaning would have. Vacuum cleaning effectively removed dust which could have hindered good adhesion.

The initial adhering using hand irons allowed for individual tensions either side of the seam to be accounted for and correct placing of each area within the whole was ensured. Further treatment on the vacuum hot table gave consistency of heating over a large area of uneven textile which could not be assured using hand irons. (A complete underlayer of a non-woven material such as Reemay could have benefited this treatment while also providing the vacuum link: this slight cushioning would protect the natural variations of surface in the textile from the harsh smoothness of the table and help closer integration of object and support during bonding.)

A combination of techniques was thought to be the most appropriate treatment to support the qanat. Stitching could have been employed alone to give overall support to the textile but would not have prevented further breakdown and loss from the already deteriorating areas. Adhesion alone would help consolidate the fibre and the weave but would not give sufficient long term support for a textile which was to be displayed hanging under its own weight.

Materials

The production of Mowilith DMC2 has recently ceased.

The Victoria an Albert Museum's Conservation Department has for some time been evaluating a number of other adhesives used in textile conservation and will now be looking at an alternative for Mowilith DMC2.

April 1994 Issue 11

- Editorial

- A saint unveiled

- 17th Century Chinese canopied bed

- Recording the changes: V&A conservation departmental archive

- The ageing & stabilisation of shellac varnish resin - an undergraduate research project at Imperial College

- Treatment of an early 18th Century Indian chintz qanat

- ICCROM - Japanese paper conservation course 1993: an introduction to the ancient skills of scroll mounting for the modern conservator

- Sand cast aluminium