Conservation Journal

Summer 2003 Issue 44

How fast do polyester fabrics age in the museum environment?

Introduction

Aromatic polyesters were discovered in 1941by chemists of Calico Printers Association (UK) and have been commercially available since 1953. Today polyester fibres are the most widely used man-made fibres. Increasingly, fabrics are given special finishes to have specific properties (e.g. aesthetic appearance, skin-moisturising effect or spill-repellent property); these fabrics are called 'techno' fabrics1 .

Not surprisingly, polyester fabrics and techno fabrics are entering museum collections at a fast pace. Polyester fabrics appear to be stable but since they have been around for only approximately 50 years, this is still an open question. In particular, the effects of techno pre-treatments, which represent a recent innovation, on the durability of polyester fabrics are unknown.

'Smart and Techno Fabrics', a collaborative project between the Victoria & Albert Museum and the Textile Conservation Centre, University of Southampton, aims at investigating the deterioration of polyester fabrics in the museum environment. A plain polyester fabric and a techno polyester fabric were subjected to accelerated light- and heat-ageing and the changes in their mechanical strength were monitored using tensile tests.

Figure 1. Plain white polyester fabric brought from John Lewis (a replicate of museum number T.118:24-1998) (click image for larger version)

Experimental

Fabric samples

The plain white polyester fabric sample was bought from the John Lewis department store, London. The techno polyester fabric,'spattering', was a replicate of a museum object (T.118:24-1998) and was provided by Nuno Corporation, Japan. This fabric is made of polyester that has been calendered mirror-smooth and 'sputter-plated' with three powdered metals (chromium, nickel and iron). This gives it a metallic shine (see Figure 1). Both fabrics were made in plain weave.

Mechanical tests

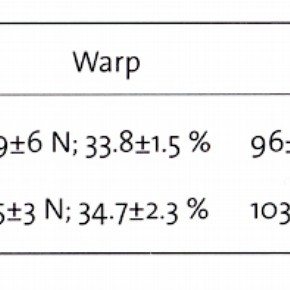

The tensile tests were conducted on an Instron machine. 19 mm wide strips of fabric were tested at a rate of displacement of 200 mm/minute with a gauge length (i.e. the length of fabric between the grips of the machine) of 75 mm. Three replicates cut along the warp and weft directions were tested every time. The load to failure and elongation to failure were measured. The results for the fabrics as received (ie, not subjected to accelerated ageing) are given in Table 1.

Light-ageing tests

For the accelerated light ageing tests, strips of fabric were placed in a light box and six samples (three cut along the warp direction and three cut along the weft direction) were removed from the light box at regular intervals. The illuminance inside the light box was approximately 9 klux and the temperature 23ºC. The ultraviolet radiation was filtered and cooling was fan-assisted.

It should be noted that museums tend to use incandescent lamps to light their exhibits. However, fluorescent lamps are used in light-ageing tests for practical reasons: they are cheap, widely available and tend not to heat up the test samples much above 30ºC, which is a problem with incandescent lamps. Fluorescent and incandescent lamps do not have the same power distribution spectra: fluorescent lamps have a continuous power distribution spectrum with discrete peaks, whereas incandescent lamps have a continuous spectrum. Thus, the deterioration of test samples illuminated by fluorescent lamps may not be the same as that of samples illuminated by incandescent lamps and the test results obtained should be interpreted with caution.

Heat-ageing tests

The polyester fabric samples were placed in an oven at 60ºC in the dark.

Preliminary tests

Effect of pleating

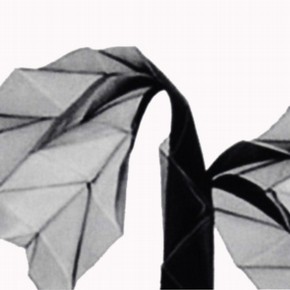

Many polyester fabrics have permanent heat-set pleats. For example, Nuno Corporation manufactures a pleated scarf made of polyester, which folds back together when laid flat ('Origami' scarf, see Figure 2). It was decided to investigate whether pleating introduces a zone of weakness in the fabric. Pleats were made in the middle of the strips across the length of both the plain polyester and 'spattering' samples using an iron heated to 130ºC. To see whether the pleats were permanent, samples were soaked in tap water and it was checked that the pleats were still present once they were dried (these samples were not subsequently tested). Pleated samples did not tend to fail along the pleats and their strength was similar to that of the non-pleated fabrics. This suggests that permanent heat-set pleats do not have any detrimental effects on the strength of polyester fabrics.

Effect of soaking

Treatments performed by textile conservators often involve using deionised water to clean fabrics. Immersing a fabric in a liquid might swell the fibres and affect their mechanical properties. Samples of plain polyester and “spattering” were soaked for ten minutes in deionised water and left to dry on a tissue. Their strength was found to be unaffected by this treatment. This suggests that cleaning treatments using deionised water do not have a detrimental effect on the mechanical strength of polyester fabrics.

Ageing tests

Light-ageing tests

A textile on permanent display at the Museum is usually illuminated at 50 lux ten hours a day2 , meaning that it receives approximately 180 klux.h per year. Samples of plain polyester and 'spattering' (with the metal-plated side facing upward) were placed in the light box for 69 days, which is equivalent to approximately 80 years in the museum. It was observed that the strength of both the plain polyester and 'spattering' did not vary significantly during the ageing tests. These results suggested that (i) the tensile strength of polyester fabrics would not be affected after 80 years of illumination in the museum environment and (ii) the techno pre-treatment on 'spattering' did not have any adverse effect on the durability of the polyester fabric.

Heat-ageing tests

Increasing the temperature of the environment is recognised to accelerate the rate of deterioration in an object 3 . After three months of heat-ageing at 60ºC no change in the mechanical properties was recorded for either the plain polyester fabric or 'spattering' and it was decided to increase the temperature to 80ºC. However, after two months, the tensile strength for both fabrics was unchanged. It was concluded that the polyester fabrics under investigation were very stable.

Conclusions

Preliminary tests have shown that putting permanent heat-set pleats in polyester fabrics does not introduce a weakness zone in the fabric. Also, the strength of polyester fabrics that had been soaked in deionised water was unaffected.

Samples of plain polyester and 'spattering' received a light exposure equivalent to approximately 80 years in the museum environment. Samples were also heat-aged in an oven at 60ºC and then at 80ºC. Following these ageing tests, the strength of both fabrics was found to be the same as for the unaged fabrics, which shows that polyester fabrics should be very stable in the museum environment. Finally, this study shows that the techno pre-treatment employed for the 'spattering' fabric has no detrimental effect on the durability of the fabric.

Acknowledgements

The financial support of the Art and Humanities Research Board for the 'Smart and Techno Fabrics Project' (project code AR13715) is gratefully acknowledged.

Thanks are also due to Nuno Corporation for providing samples of 'spattering', the Courtauld Institute, the National Gallery and to Imperial College for the use of their Instron machine.

Finally, I wish to thank Brenda Keneghan and Graham Martin from the Science Section and Paul Wyeth from the Textile Conservation Centre for their help and support.

References

1. Braddock S E & O’Mahony M, Techno Textiles. London: Thames and Hudson, 1998.

2. Thomson, G, The Museum Environment. Sutton UK: Butterworths, 1986.

3. Feller, R L, Accelerated Ageing Photochemical & Thermal Aspects. USA: The Getty Conservation Institute, 1994.

Summer 2003 Issue 44

- Editorial

- Sustainability and precaution: Part 2 How precautionary should we be?

- Strand Palace Hotel

- How fast do polyester fabrics age in the museum environment?

- Materials and their interaction with museum objects

- Problems associated with the use of gloss house-hold paints by 20th century artists

- Shooting yourself in the foot: the do’s and don’ts of working with weapons

- Understanding conservation: An evening course at the V&A, 29 January – 26 February 2003

- Printer friendly version