by Dafni Daskalaki-Mountanou, MSc student Imperial College / V&A

The predominance of polymers in everyday life is obvious. They have become an integral part not only of everyday objects but of cultural heritage objects as well. A survey held in the 1990s at the Victoria and Albert Museum showed that large numbers of artefacts were partly or completely made of plastic polymers and had already ‘lived’ longer than was expected when they were produced. Consequently, the demand on plastic restoration has increased significantly.

Scientists and conservators have been developing various techniques for preserving polymers and cleaning their surfaces for many years. This is a promising but complicated field because it depends on the type of plastic that needs conservation and the condition of the object, and polymers present a diverse range of properties and degradation profiles. Scientists and conservators have been working extensively on conventional cleaning treatments such as mechanical or solvent-based cleaning. The potential damage caused by those means and the growing opportunities of cleaning with lasers gave rise to this project.

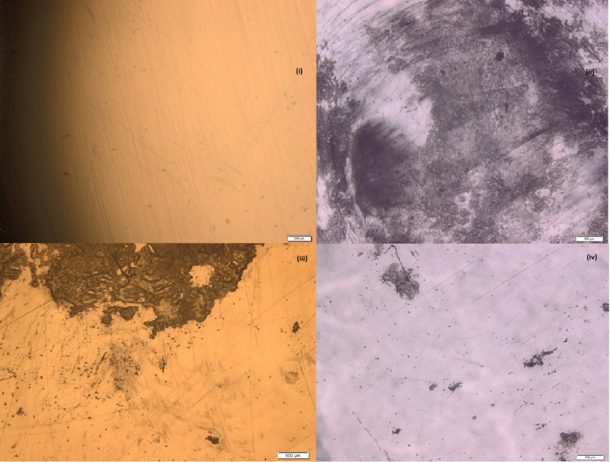

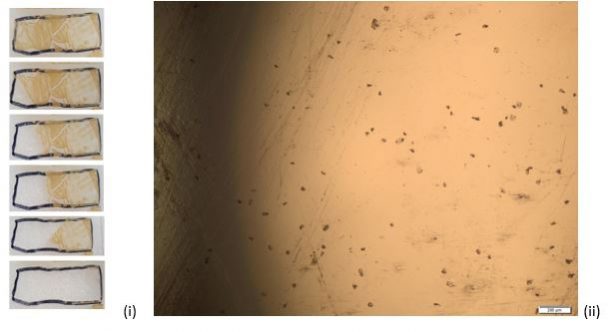

The successful use of lasers in different fields (medicine, industry, cosmetics etc.) has now extended to the field of cultural heritage. Lasers have proved to be a highly efficient tool for cleaning artworks. Additional advantages include higher accuracy than traditional cleaning methods, the ability to control removal rates and to select precise spot sizes up to micrometres. Numerous studies have been conducted in order to investigate the potential and limitations of lasers for cleaning artefacts. This collaborative project between the V&A and Imperial College of London investigated the interaction of an Er: YAG (erbium-doped yttrium aluminium garnet) laser with plastic objects. Er: YAG lasers are the most recent lasers used in conservation, and they have presented promising results in various materials such as stone, marble, metals and contain many advantages when compared to different laser types. This research was carried out in two parts. The first focuses on estimating the permanent physical or chemical damage induced by the laser (Figure 1ii). The second part includes some preliminary trials of cleaning polymer samples (Figures 1i, 1iii and 2).

A series of experiments took place in order to investigate the efficiency of cleaning different types of polymers under different experimental conditions (e.g. exposure times and surface conditions such as wet and dry) and if any damage occurred in the process. Results were different for each polymer and each experimental condition. Polystyrene (PS) and Plexiglas® (poly methyl methacrylate, PMMA) presented the most promising results whereas laser treatment proved inadequate and even catastrophic for nylon and fibreglass.

The preliminary experiments carried out during this project revealed some interesting information about the interaction of an Er: YAG laser with polymers. PS and PMMA samples contaminated with residues of tape adhesive were cleaned by laser and compared with traditional mechanical cleaning (Figure 1iii). It was found that the laser cleaning was more efficient and did not cause damage to the samples. These results have underlined the necessity of investigating further the nature of plastics and how they interact with the laser. It is now the time to explore the possibilities of the use of the laser further.

Acknowledgements

I would like to thank Brenda Keneghan and Boris Pretzel for guidance during my project.