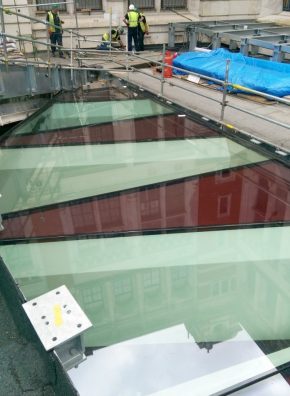

Over the past six months, the team has enjoyed watching the construction of the oculus develop and take shape on site. Now that work has completed on the concrete structure, the Exhibition Road building project is ready for bespoke steel and glass elements to be installed, and installation of the Oculus has begun. This eye-catching structure in the middle of the courtyard has been developed by the project architect AL_A with Dutch design and build contractor Octatube.

What is the Oculus?

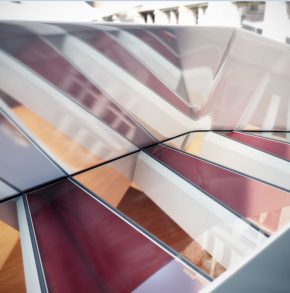

The Oculus functions as a skylight, allowing natural light to permeate the new galleries and creating a visual connection to the historic Aston Webb-designed buildings of the V&A by allowing visitors to look up out of the galleries and see the upper storeys of the buildings surrounding the courtyard. The Oculus is surrounded by a stainless steel balustrade with bespoke finishes. It is glazed with exceptionally clear, high specification glass, illuminating the spaces below with natural, indirect light, ideal for the display of select objects.

The Balustrade

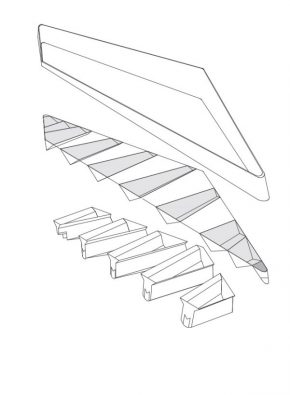

The Oculus is encircled by a steel balustrade with a complex, double curved geometry. In total the balustrade is 45 metres long and consists of four parts that are connected by thermal expansion joints, which release the tension caused by changes in temperature. The largest solid part is 12 metres long.

“The intention of AL_A was to have the exterior of the balustrade as smooth and flat as possible, even though the structure contains complex curves and angles,” explains engineer Kuno Jacobs who was in charge of the design development, “so nearly all fixings and brackets are unique and were specially made to make them practically invisible in the structure. For the outer surface we used a technique called ‘shot peening’ which uses high pressure ceramic blasts to get rid of any irregularities to create a high quality matte finish. The inner surface of the balustrade is composed of mirror polished stainless steel which enhances the collection of natural light and gives the balustrade its grand appearance.”

The Vitrines

The glazing of the Oculus is composed of rhombus-shaped prefabricated units known as ‘vitrines’. Each unique in size and shape, the vitrines are stainless steel boxes, structurally sealed with glass, designed to resemble the gallery’s ceiling and structure. Octatube performed several environmental, structural and airtightness tests over the span of a year to ensure the vitrines stay in perfect condition under any circumstances

To test how climate and temperature would affect the vitrines and materials, a test assembly of three vitrines went into an environmental chamber. Temperature inside the chamber was set on 66 degrees Celsius, which is the estimated temperature of the vitrines during hot summer days.

“We installed small pipes (valves) in each vitrine to filter the air and regulate the pressure and relative humidity. This way, the vitrines are capable of breathing without the risk of collecting dust,” said Thomas Been, Octatube’s project manager.

The vitrines were produced in the Netherlands. They received a lacquer coating in a car workshop, using paint created for cars, to give the material a luxurious, hardwearing finish. Finally, they were sealed, loaded into a cargo container and transported to London by truck. The largest vitrine container is 5.5 metres long and weighs about 1 ton. At the building site, the vitrines were carefully installed in place by use of a crane. The balustrade will be installed later this autumn.

About Octatube

About Octatube

Dutch specialist façade subcontractor Octatube is in charge of all bespoke external glazing and metal finishes, consisting of the Oculus and staircase skylights, cafe and shop facades, and the glass link between the existing Western Range building and the new V&A shop. For these constructions, Octatube is responsible for the designing, engineering, building and installation.

If you would like to know how you can support the Exhibition Road Project, please visit: http://www.vam.ac.uk/info/exhibition-road-appeal

Fascinating article and great conservation work of the exhibition gallery. Heritage tourism plays a huge role in the UK economy, attracting both international and domestic tourists and can provide a source of revenue to maintain historical sites. Surprisingly, an oculus, originating in antiquity, it is a feature of Byzantine and Neoclassical architecture. It is also known as an œil de boeuf from the French, or simply a “bull’s-eye”.

This is a great project about the installation of oculus. Thanks for sharing this post with us.

Find some new things and awesome thoughts that I’m searching for.Thanks,dear!!