While the Shekou Project is an exciting opportunity to collaborate internationally, it also brings with it a host of complex cross-border challenges. In a series of blog posts called ‘Managing Abroad’, the Shekou team’s project manager, Alex Willett, explores some of these lesser discussed, but fundamental issues, to managing global projects.

For the past few decades, China has held a firm position as the centre of the manufacturing world, and today low-cost manufacturing still largely drives China’s booming economy. So when it comes to the build and production of the V&A Gallery in Shekou, it made sense that we should source a lot of production locally. But with the spate of sensationalist reporting in documentaries and books such as ‘Poorly Made in China’ is it true that low-cost manufacture also means low quality?

With a view to picking this apart and to establish some due diligence, Annabel Judd (Head of Design) Mandy Ward (the V&A’s expert on showcases) and I set off on a whistle-stop tour of display case manufacturers working in China.

While the average visitor might not give much thought to museum display cases, they are the bane of the exhibition designer. Essential to the security and conservation of the objects and the most costly part of an exhibition display, they are also incredibly difficult to design well. On top of that, it is a highly skilled, small and competitive industry. So I wondered just how happy manufacturers would be to welcome us into their factories. My fears, as it turns out, were unfounded as the companies we visited were all generous and hospitable; happy to show us their factories, view their case showrooms and discuss their various products.

Inside the factory

We started with Tianjin Wangda Exhibition Products Co. Ltd., and Langfang Wen Bo Exhibition and Technology Development Co. Ltd. – both just outside of Beijing. Their facilities were smaller than I expected, with very little machinery on-site, clean with an open assembly space and a quantity of case parts in production. They both had showrooms with a range of standard cases but some innovative ideas such as incorporating a light mat on top of a glass-topped free-standing case.

After three days in an unusually blue-skied Beijing, we flew to Chengdu, to visit Relicase Display Systems Ltd. This was a slightly bigger facility, with demarcated areas for different manufacturing processes, including sorting glass deliveries (some of which they ship in from Europe). All three of these companies produced cases that were at least three times less expensive than the ones produced in Europe.

Blue skies over Beijing

Which takes us back to our original question: does low-cost mean low quality? One point of reference we were using was the National Museum in Beijing, which has worked with all three of these companies. This already gives us a large vote of confidence, as the nation’s most representative museum space is not likely to settle for poorly-made cases. There are some differences to consider though. For instance, the National Museum often chooses a design aesthetic of wood and marble, very different from the metal cases the V&A would usually work with.

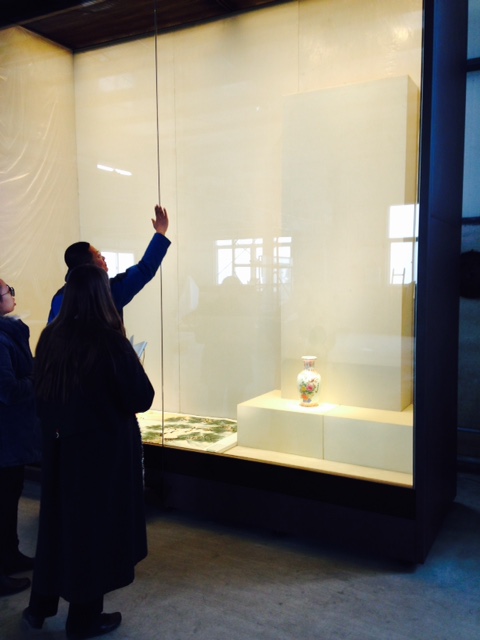

Inside the National Museum in Beijing / One object, one showcase

Another consideration is that the V&A in London does not air-condition the galleries; so the showcases play a fundamental role in keeping the environment stable, having a very low air exchange rate. At the Shekou Design Museum, the galleries will be air-conditioned; therefore there is an argument that the air-exchange rates don’t need to be to tight. Where will the lines of best practice and most appropriate specification for the institution meet?

Also, Chinese museums tend not to use shelving or internal case fittings, as each object is treated as an individual work of art. For our exhibition, objects will be displayed adjacent to others, in groups or animated through different mounting techniques. By exploring the options for shelving and internal fittings, will we be moving these manufacturers out their comfort zone?

Ultimately we felt encouraged by our research experience, confident that the questions we raised were resolvable. As with every exhibition build, we will work closely with the contractors during the production period, and an open dialogue can help us fix issues before they happen and make sure we get the quality we need.

The next step is to appoint an exhibition designer to visualise what the exhibition will look like and what display cases we need. They will be working with our display case specification to design the cases to meet the needs of the objects and the aesthetic of the gallery. After that we will be back in touch with the display case manufacturers and possibly others, to find a best fit for the end product. Lower costs and shorter production times may be tempting, but the quality of design and performance of the display case is the ultimate target.

With thanks to our translators and research companions Wu Sichao and Luisa Mengoni who, with me, have now quadrupled our understanding of the world of showcases.