by Anne Bancroft, Senior Book and Paper Conservator and Samantha Hare, Student Book Conservator

This article discusses the conservation of a textile sample book (TN.590-2012) and a unique approach to the preservation of the textile samples within it. The album is one of over five hundred textile sample books held by the Victoria and Albert Museum. This is one of the many collections that will be moved to the V&A’s new Collection and Research Centre in the Queen Elizabeth Olympic Park. In preparation for the move a survey was carried out to identify albums in Poor and Unacceptable condition in order to stabilise and box them prior to their migration. A Museum-wide system is used to describe the condition of objects: Good; Fair; Poor; and Unacceptable. One of the albums which was in Poor condition required a substantial amount of treatment due to notable water damage, resulting in losses and degradation affecting the samples and the substrate. Although the textile samples were primarily cotton or a silk/cotton blend, this album also housed silk samples that had fractured due to inherent acidity, stress from the volume, and interaction with moisture. An innovative solution was devised to support and prevent further deterioration and loss of the fractured silk by facing the samples with Melinex spot welded onto Japanese hinges within the text block.

Originally from Skipton Mill in North Yorkshire, England and dating from 1910, this album is typical of textile sample books of the period. Suzy Shepherd, a founder and director of Leeds Fashion Works and Yorkshire Textiles Ltd., describes the impact that cloth manufactured in Yorkshire has had and how valuable the mill archives are for appreciating this contribution:

With its rich and unique textile heritage, Yorkshire is renowned for producing some of the world’s finest and most sought-after cloth. Leading luxury brands around the world, couturiers, Savile Row and Royalty are just some of the destinations for cloth produced in Yorkshire. Many of the mills can trace their roots back through generations. The iconic scarlet cloth of the Queen’s Guard’s uniforms is one of the instantly recognisable cloths made in Yorkshire.

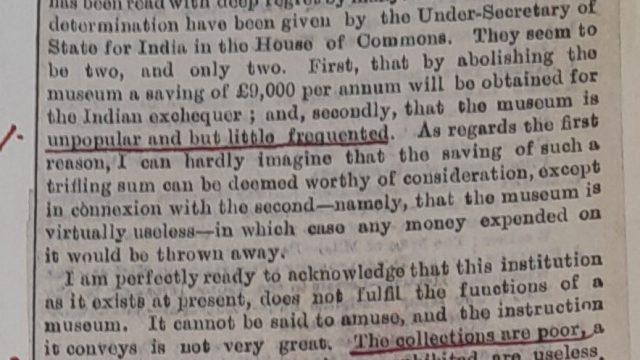

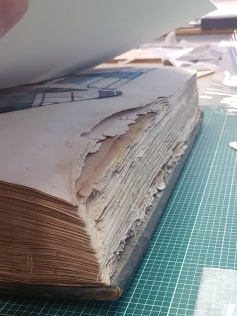

Prior to entering the V&A’s collection, the album was in the possession of the Craven Institute of Further Education where it is suspected that it was exposed to damp conditions. It is half leather with cloth sides sewn on three tapes incorporating compensation guards and made endpapers. It was in poor condition with extensive damage to the edges of the textblock and endpapers due to moisture and mould. The textile samples were also affected by mould damage, staining and planar distortion. The silk samples attached to 61 pages, or approximately 40% of the volume, were fracturing where attached, detaching from the paper and creasing from pressure put upon them by the weight of the textblock. Many of the samples have aqueous staining associated with the degraded and mould damaged fore-edge (Figure 1).

The album could not be opened without the risk of damage and loss of the paper and the samples. Firstly, the conservation of the paper was tackled: the losses were infilled with Japanese paper and tissue which matched the tone and weight of the original leaves. The damaged edge of the ‘made’ flyleaf was split in order to insert a Japanese support paper which was then lined with a Japanese tissue toned green to match one side and cream the other. This was subsequently sized with methylcellulose for consistency with the original sheen.

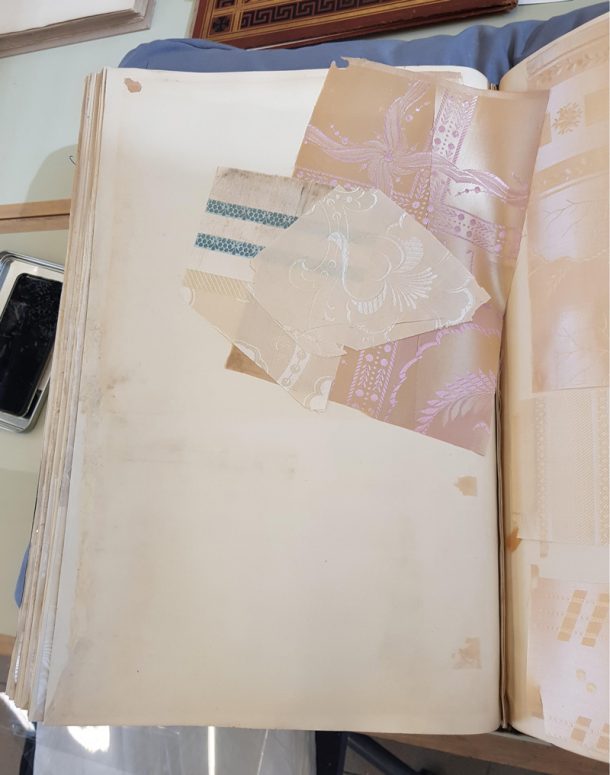

After consultation with a colleague in Textile Conservation, each sample was locally humidified to relax creases. Sympatex, a semi-permeable membrane, was used to control the amount of moisture reaching the textile. Following humidification, the samples were subsequently pressed with blotter in their original position. After drying, the samples were re-adhered with Jin Shofu wheat starch (WSP) utilizing the previous adhesive staining at the corners as a guide. As it was not possible, due to resource constraints, to fully conserve each sample, the aim was to find a way to protect the silk from further damage until appropriate, extensive textile conservation could be carried out (Figure 2). Any solution needed to provide adequate protection to hold the silk securely in place, as well as facilitate safe handling. Possible temporary solutions had to be reversible without risking damage to the substrate or samples and interleaving options within the textblock necessitated minimal swelling to prevent compromising the binding structure. As always, the solution had to be time efficient and economical as the treatment would have to be applied to 40% of the volume.

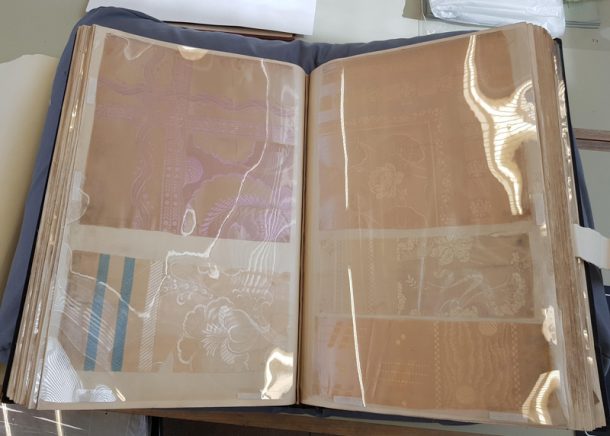

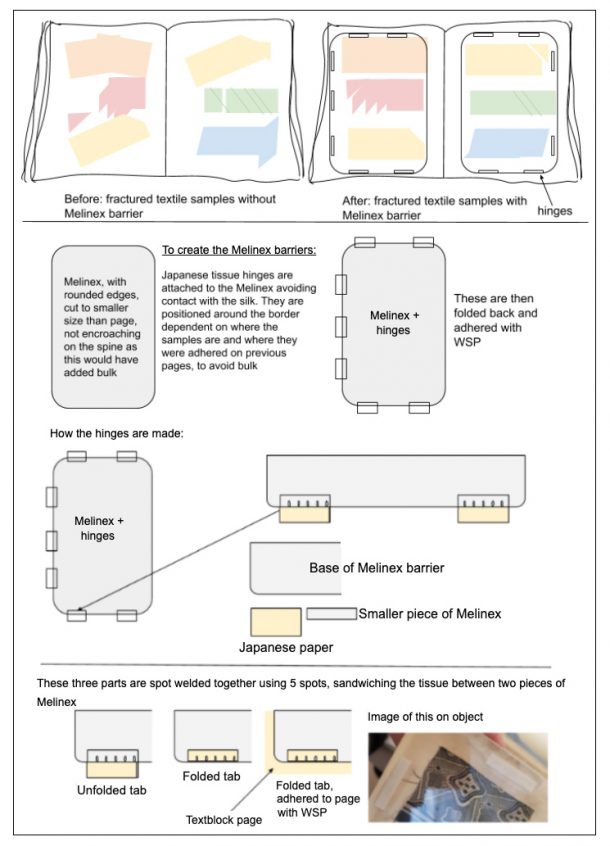

Taking all of this into account, a Melinex interleaving barrier was devised to hold the samples in position (Figure 3). A thin inert Melinex was chosen for its transparency, its static charge that holds the samples in place when it is attached to the page and because it would be compatible with the flex of the substrate whilst turning the page. The sheets were cut to just under the height of the textblock, and narrower than the page width so they did not encroach into the gutter causing bulking to the binding structure. The Melinex was rounded at the edges to remove sharp corners that could cause damage. Melinex and Japanese tissue hinges were welded in bespoke positions at the head, tail and fore-edge. The positioning varied for each page to spread out the bulk throughout the volume and was also dependent on the position of the silks. The hinges were constructed by spot welding through a smaller piece of Melinex and the sheet of Melinex, sandwiching a hinge of Japanese tissue in between. These hinges were then folded back and adhered with wheat starch paste to the substrate, positioned where possible on the infilled areas of the fore-edge (see Figure 4 for a step-by-step guide with visuals). The album was boxed in a bespoke acid-free phase box with a label that indicates it has had previous mould activity.

This treatment was an innovative way of protecting textile samples that are housed within a binding. The composite nature of the object necessitated cross-disciplinary collaboration to forge a temporary and effective solution, bearing in mind that temporary solutions have a habit of becoming permanent.