by Gabrielle Crowther, Stefani Cavazos, and Netanya Schiff,

UCL MSc Conservation for Archaeology and Museums

The Textile Conservation Studio at the Victoria and Albert Museum is currently trialling cleaning textiles with the aid of an ultrasonic unit developed by Harry Singh of HDS Ultrasonic Ltd (Figure 1). As part of this project the authors have analysed test cleaning samples using Scanning Electron Microscopy (SEM) to observe potential damage caused by the ultrasonic cleaning system to the textile fibres.

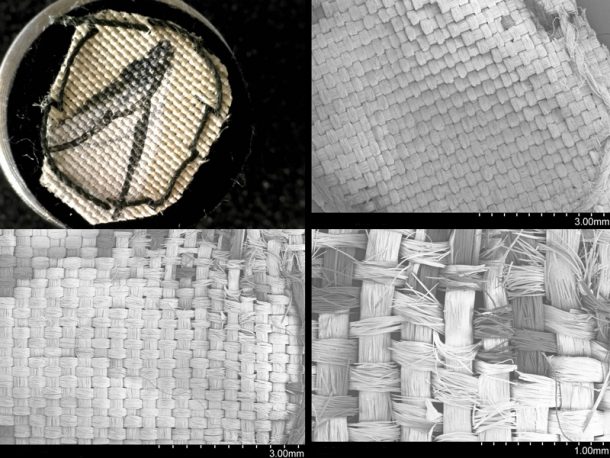

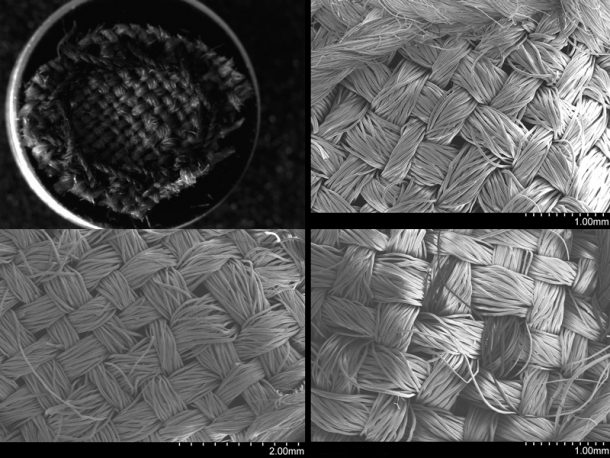

Four samples of historic textiles from a reference collection held at the V&A were immersed in de-ionised water and cleaned with the ultrasonic unit. The sample types were chosen by conservators to be representative of common cleaning challenges due to either age, fragility, or other inherent characteristics of their material composition. Through the SEM investigation, the researchers sought to better understand the mechanical effects of the ultrasonic cleaning on each type of historic textile individually, as well as to compare the damage caused with and without the use of a Melinex barrier between the ultrasonic device and the textile surface. The effectiveness of cleaning was not a focus of this analysis.

Removal of deeply embedded soil and staining from textiles often relies on wet cleaning methods in combination with agitation of the textile fibres to dislodge unwanted materials from the fabric body, which can result in damage to the textile fibre. Removal of ingrained soiling during immersion is traditionally done with brushes and sponges in direct contact with the textile to encourage the migration of soiling and stains into solution. Ultrasonic cleaning provides a controllable micro-agitation system to remove more persistent embedded soiling, which offers a localised treatment and eliminates the need of excessive direct physical contact with the object, reducing overall manipulation.

The ultrasonic unit being tested has an amplitude of 40 kHz with up to 50 W of power and consists of a control box with a wand attachment. The size of the wand head is 10mm. The unit works similarly to ultrasonic baths, by using sound waves to agitate a solvent, generating cavitation bubbles that provide gentle abrasion to break down soiling. The wand attachment on this instrument is the transducer, which allows more localized cleaning. In order to analyse the potential damage of the ultrasonic device on textiles, samples were prepared in Textile Conservation by MA student placement Lauren Osmond. The textiles investigated included wool, silk embroidery, painted silk, and cotton chintz. These samples were chosen based on their similar degree of soiling and structural stability. Each sample was marked out with six sample areas and a seventh control area which was not treated. The six sample areas were then submerged in a bath of deionized water and cleaned with the ultrasonic wand as follows:

With the wand held in one position and in direct contact with the fabric

- 25 seconds

- 10 seconds

- 2 seconds

With the wand in continual movement with a Melinex barrier between the sample and wand

- 25 seconds

- 10 seconds

- 2 seconds

These times were chosen in order to determine at which point visible damage could occur due to direct contact between the wand and the surface of the substrate. The samples were prepared for SEM by cutting around the sampled areas and mounting on aluminum stubs. They were then examined and photographed using a Dino-Lite Pro HR AM7013 MT at 20x magnification in raking light. Images produced with the Dino-Lite were used as points of reference, to create a comparison between visible and microscopic damage to fibres caused by cleaning.

The samples were gold coated to enable conductivity using a Quorum Technologies Q150R ES gold coater. Qualitative investigation of the samples was then conducted with SEM imaging using a Hitachi S-3400 N scanning electron microscope under 5.00kV accelerating voltage at varying magnification (between x16-950). Secondary electron images were captured to observe detail of surface morphology, and images were focused on areas of mechanical damage, if present.

Across all textile types tested, the damage was most pronounced when the wand was held in direct contact with the sample for an extended length of time from two to 25 seconds, with 25 seconds representing the most extreme case of damage. The two silk samples exhibited the most damage of the four textile types, likely due to the inherent fragility of this material (Figure 2). However, in all textile types, negligible damage was observed when the textile was first covered with a Melinex barrier and the wand was continually moved across the sample, rather than held in one position. This represents best practice and should be included in the recommended methodology accompanying use of the ultrasonic wand for cleaning.

Although it is difficult to make definitive recommendations for the use of the ultrasonic unit, as all textiles tested were historic and had unique states of degradation and soiling prior to analysis, the cleaning of wool with the instrument appears to be safe when a Melinex barrier is used in combination with continual lateral movement across the textile surface (Figure 3). Cotton chintz also appeared to be unaffected by cleaning despite its degree of historic degradation prior to testing. Methods of systematic movement to ensure even cleaning and minimal damage should be the next area of practical experimentation. V&A textile conservators have achieved satisfactory results in removing persistent soiling with practical use of the ultrasonic unit, and it is hoped that the findings of this SEM investigation have contributed to more specific recommendations for safest methods of cleaning.

Acknowledgements

We are grateful to Harry Singh for his cooperation and support as well as to Frances Hartog, V&A Senior Textile Conservator, Joanne Hackett, V&A Head of Textile Conservation, and Lauren Osmond. Thanks to University College London Institute of Archaeology Wolfson Archaeological Science Laboratory for access and Tom Gregory, UCL SEM technician, for support using analytical equipment, as well as Caitlin O’Grady, UCL Lecturer in Conservation, for the first stage of editing.

I would like to thank you for this very worthwhile research.

Please feel free to contact me if there is anything I can do to assist you with this or any other project.

With Regards

Harry Singh