Jonathan Fletcher MRICS is a Technical Specialist at Plowman Craven, UK’s leading specialist chartered surveyors in 3D scanning.

One of the most famous statues in the world is Michelangelo’s depiction of David as he stands poised to face the giant Goliath, armed with the latest technology of his time, a trebuchet sling. Armed with some of the latest technology of our time, laser scanning experts from Plowman Craven recently created a precise digital model of the V&A Museum’s spectacular plaster cast of this iconic statue (see previous post here).

Made in the 1850s, David resides amongst other casts of masterpieces in the V&A museum’s Cast Court… but the 2017 digital model will soon be going global, having been commissioned for use in the new Ridley Scott movie, Alien: Covenant. Working from our digital model, the film-makers created an exact, full-scale replica that was cut in foam using a CNC machine.

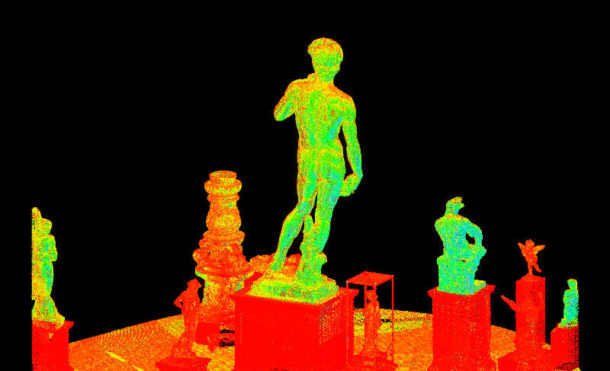

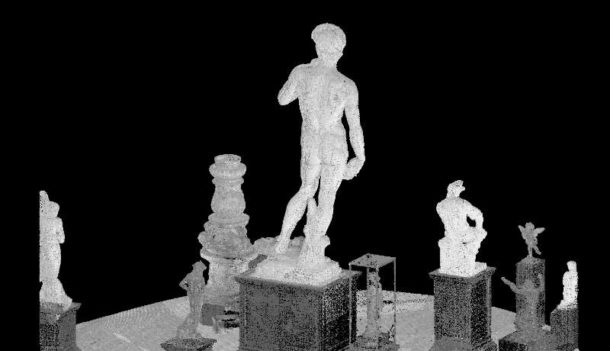

Standing at more than 5m tall, on a 1.8m-plinth, David has Goliath proportions of his own. In order to capture his intricate details – such as the veins and the trebuchet sling handle held in his right hand – millions of ‘points’ on the statue were captured using a state-of-the-art LiDAR laser scanner.

By moving the scanner to multiple locations in the room – including the balcony of the Cast Court – we were able to avoid shadowing, capture every single inch of David and create an exact high-resolution mesh. Any miniscule gaps in the meshed data were then filled in using high-resolution digital photography.

The digital model of David is so accurate to the cast that it even includes the joint seams created when it was made from the original in Florence. Many of these seams are not visible to the naked eye in certain light conditions but appear in the mesh as it is not subject to a light source. Our VFX department used bespoke modelling software to smooth out the seams, ensuring that David was identical to the original ahead of his big-screen debut.

While scanning the David cast we also produced data on this Nymph (Mus.no REPRO. 1864:1-104).

The unanticipated by-product of this undertaking was an improved understanding of the network of joints in the cast which may hopefully help the V&A’s Sculpture Conservation team to investigate how the cast was templated and created.

Ideas for further investigation

A very detailed scanning exercise was undertaken of the Florentine original, a book was even written about how it was done. Having access to that data we would be able to undertake a comparison on how different the cast is to the original. This may show areas of weathering as I believe he was still outside when he was cast. It could also show deformation of the original or the cast, and we could also compare models the Moscow and Brussels casts to show if they are deforming or any differences (weathering/degradation of the original over time).

Notes

- 3D laser scanning works by firing a laser at the subject (typically an object or building) at more than a million points per second. That information then forms what is called a point cloud, with every point and pixel within that accurate to plus or minus a few millimetres. This point cloud can then be used to create a 3D model.

- LiDAR scanning of a painted cast of David would provide a better representation of him as the laser may penetrate the Carrara Marble of the original creating a ‘noisy’ surface (rather than bouncing straight back to the scanner). Strangely, dust and dirt on the original would provide better data… in fact, our movie special effects department sometimes uses talcum powder to recreate these conditions when scanning props.

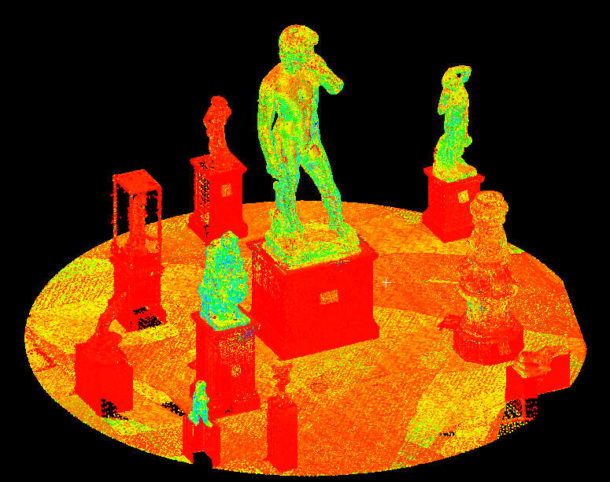

- We scanned David in context of the other statues, the geometry of all these other statues and the shape of the Cast Court building helped to align the point cloud to get a more accurate representation of David.

In the next post, Production Designer Chris Seagers from the film Alien: Covenant describes the different processes of creating the model. Stay tuned for Michelangelo’s David – Part 3: Constructing a full-scale model